AUSTRALIA WIDE DELIVERY Demos Available in SEQ, Syd & Melb only

SAVE WATER SAVE WASTE SAVE TIME

PRODUCTIVE CONSTRUCTION SITE

SMART SINKS

-

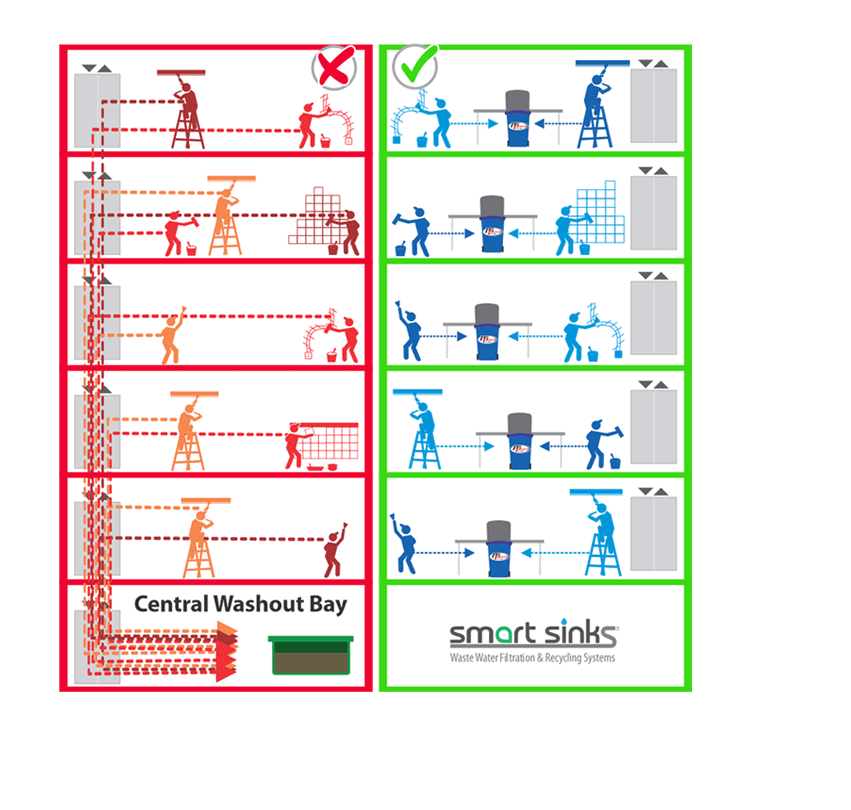

REDUCES movement of personnel around the site

-

REDUCES lift use

-

REDUCES water use through recycling

-

ELIMINATES waste management issues

-

NO sediment in drains/tradewaste

Perry Richardson, Managing Director of Pro Plaster, exclusive Australian distributors of Mobile Smart Sinks, commented:

"The feedback we've had from our customers has been amazing. They can't believe how much time and money the Mobile Smart Sinks units are saving them."

"Whereas in the past, tool washing/washout was taking an average of 15-20minutes by the time they traveled to and from the basement and used the shared central washout facility, by having the washout facility right there with them at the work face, they're able to complete the process in around 5 minutes," Perry said.

Together with its enviable reputation for saving thousands of litres of water per week through recycling, preventing waste sediments being flushed into pipes and/or stormwater, and saving plasterers and tilers an average of over one hour, per person, per day in time spent moving between the work face and washout facilities.

The remarkable Australian-designed and internationally patented Mobile Smart Sinks unit has also become an invaluable front-line tool in helping to establish COVID-SAFE construction sites.

By providing tool washing/washout facilities at the work face rather than at a centralised location, Mobile Smart Sinks units not only save time, save waste and save water - they help to significantly reduce movement around the construction site while also eliminating issues associated with social distancing and maximum density requirements at centralised tool washing/washout locations.

Smart Sinks Is Perfect For:

PLASTERERS

RESIDENTIAL

COMMERCIAL

GOVERNMENT

PRODUCTIVE

While there can be no doubt that Mobile Smart Sinks have set a new benchmark in waste sediment control, water saving and productivity gains for tilers and plasterers, they have also, quite unintentionally, proven to be a critical front-line tool in establishing COVID-SAFE construction sites.

By providing a tool washing/washout facility at the work face rather than at a traditional centralised location (usually in the basement), Mobile Smart Sinks significantly reduce movement around the construction site, including lift usage.

They also eliminate issues associated with social distancing and maximum density requirements at centralised tool washing/washout locations.

Solving today's problems for a better tomorrow.

by BUILD Construction & Engineering

-

REDUCES movement of personnel around the site

-

REDUCES lift use

-

IMPROVES social distancing & hygiene

-

NO LOST TIME travelling to and from central washout facility

-

REDUCES water use through recycling

-

ELIMINATES waste management issues

-

NO sediment in drains/tradewaste

-

Multiple movements between worksite and washout facility

-

Social distancing & hygiene challenges

-

Lost time & productivity travelling to and from central washout facility

-

Increase water use

-

Waste management challenges including sediment in drains/tradewaste

Our Smart Sinks Brochure

-

Significant water savings

-

Massive productivity boost

-

Cost effective solution

-

Covid-Safe Construction sites

-

World-Leading Australian Innovation

-

Patented filtration technology

Demos Available in SEQ, Syd & Melb only.

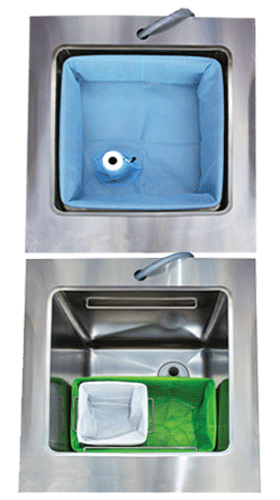

No chemicals are needed with this sink design. The whole system is run off filters and avoids the use of messy or harmful chemicals.

Depending on use, we recommend emptying the sink every week. This is as simple as spraying the water into buckets and pouring them into a drain as it is Trade Waste approved. When there is no more water left, simply refill the sink with the tap water available on site.

You should empty the sink to avoid stagnant water, as regardless of water quality, stagnant water will smell.

There are two ways to fill up the sink which has a 60 litre capacity.

1. Pour buckets directory into the top blue filter (approx. 5 regular topping buckets) - turn the machine on and allow to run for a couple of minutes before use to prime the filters.2. Attach a hose to the connector on the back housing where the pump is located, ensure the tap is in the open position and the small clear filter plate is clean. (This fills the sink up filter first and can be used straight away as it's already primed).

With both methods, the machine needs to be turned on. Fill the sink until the 3rd light comes on, which is located on the side of the bin. These lights are at water level sensors where:

The 1st light signals that the sump is full and the sink is stable,

The 2nd light signals that there is minimum water level to operate,

The 3rd light is that the water level is getting close to maximum.

The 4th light (which also has audible alarm) signals that the sink is too full, and water needs to be sprayed out of the machine.

The filters are disposable and need to be regularly changed to ensure the sink works efficiently. We do not recommend washing the bags and reusing them, as this can damage the bags and cause larger particles to filter through, reducing the integrity of the system.

The Blue Filter Bags should be changed daily.

The White Filter Bags should be changed weekly.

The Green Filter Bags should be changed each 2 weeks as NO bag should be left in unit for more than 2 weeks.

The Filter cartridges should be changed monthly.

These are a guide and are subject to use. Visual checks should always be performed to see if the bags are causing blockages with excess material.

You can order more filters by simply contacting sales@proplaster.com.au or by calling 1300 PRO PLASTER.

The current system is not designed for oil-based products like paint, this causes properties of the pain to bypass the filters and damage the cartridges at the back of the sink. A clear way to see if this has occurred is a 'milky' look to the water in the back cartridges. The paint also blocks the pump causing pressure loss and a stagnant smell.

A unique filter is currently being designed to absorb the pain properties, so stay tuned for a painter friendly version of smart sinks!.

2. Check the filter bags are clean and don’t need replacing.

3. Check that Painter haven’t used the sink and blocked the pump in the sump (by removing the collection units).

*As always, dump most of the excess product in a suitable bin before washing out the tool.

A water source is required to initially fill up the machine, whether that’s on or off site.

It’s heavily recommended to empty the sink of water before transporting. The sink ideally should be upright but it can be laid on its side. Avoid lying the sink on its back which will put unnecessary pressure on the back filter cartridges.

The wash trays can be easily removed to slim the machine down or to reduce the weight.

Multiple trades can use the sink, from Concreters, Tilers, Plasterers etc.

It’s easily transported from site on the back of ute.

It’s Reliable - low maintenance and little moving parts means that in the 3 years they’ve been operating -we’ve yet to have one break.

It’s odourless.

It’s Eco-Friendly - The Smart Sink is an award winning Washbay. Wining an award every year for the last 3 years since it’s been operational. The most recent award is the “Most Eco-friendly Tool Washing System” 2020 at the Build Constructions and Engineering Awards – an global competition.

-

SIGNIFICANT Water Savings

-

MASSIVE Productivity Boost

-

COVID SAFE Construction Site

-

COST EFFECTIVE Solutions

-

WORLD LEADING Australian Innovation

Stainless Steel Bench with 3 stage filtration system.

Packed: Height H1140mm x W945mm x D920mm

Full standing setup: H1295mm x W2190 x D920mm

- Currently we offer Australia-Wide Shipping.

- Please be aware that the current situation with COVID-19 may effect shipping times for some carriers.

- We are doing our absolute best to deliver your package as soon as possible.

Read our Terms and Conditions

Australia Wide Delivery

Made In Australia

EASY TO USE